Day 2 - Cleaning of all parts, laying of cabling, and assembly begins.

View fullsize

![Will and Clark look over the power supply rack]()

Will and Clark look over the power supply rack

View fullsize

![This is what happens when a power supply is transported incorrectly. This happened several years ago.]()

This is what happens when a power supply is transported incorrectly. This happened several years ago.

View fullsize

![Power supply is delivered to the workshop from its storage facility]()

Power supply is delivered to the workshop from its storage facility

View fullsize

![Getting ready to move the first section, with the cabling, to the work area.]()

Getting ready to move the first section, with the cabling, to the work area.

View fullsize

![Blowing compressed air through the structure to remove years of grime.]()

Blowing compressed air through the structure to remove years of grime.

View fullsize

![This process only takes about fifteen minutes, though more cleaning will be necessary later.]()

This process only takes about fifteen minutes, though more cleaning will be necessary later.

View fullsize

![The final touches of air cleaning before the section is moved into the shop.]()

The final touches of air cleaning before the section is moved into the shop.

View fullsize

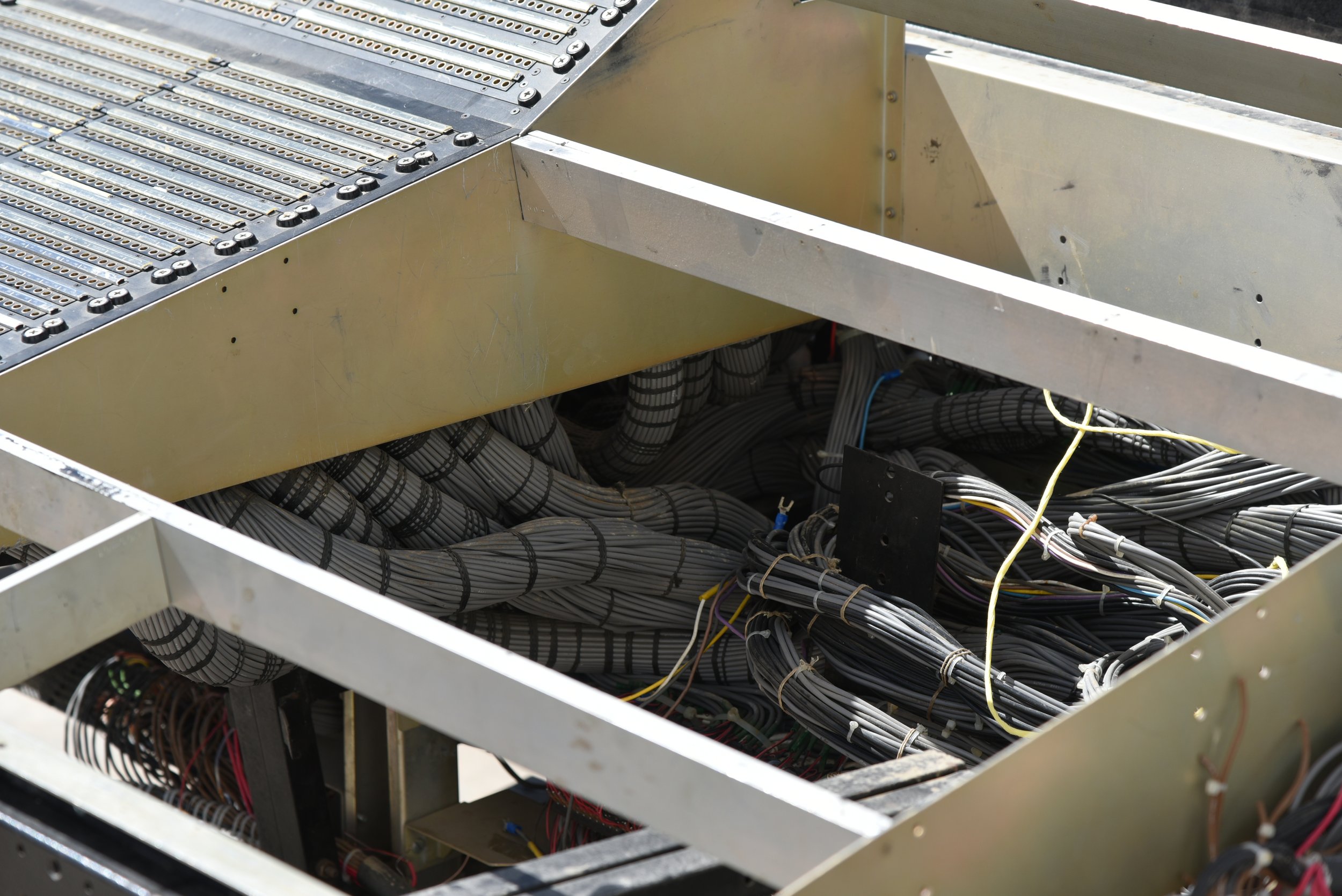

![The back of the initial section, with the wire looms and terminations visible. All of these connections and crmips were done by hand.]()

The back of the initial section, with the wire looms and terminations visible. All of these connections and crmips were done by hand.

View fullsize

![All Olive wiring, as with many other consoles, is hand-sized and soldered. No automation in this process.]()

All Olive wiring, as with many other consoles, is hand-sized and soldered. No automation in this process.

View fullsize

![The amount of cabling is almost unbelievable, and while the work is exacting, creation of the looms is also extremely time-consuming and tedious.]()

The amount of cabling is almost unbelievable, and while the work is exacting, creation of the looms is also extremely time-consuming and tedious.

View fullsize

![Looking through the top of the empty section, into the patchbay wiring harnesses.]()

Looking through the top of the empty section, into the patchbay wiring harnesses.

View fullsize

![The monitor and return sections, waiting to be inserted.]()

The monitor and return sections, waiting to be inserted.

View fullsize

![Time to bring the first section into the shop for cable layout.]()

Time to bring the first section into the shop for cable layout.

View fullsize

![Cables get untangled and laid out, in anticipation of the next set of bays.]()

Cables get untangled and laid out, in anticipation of the next set of bays.

View fullsize

![Here, extra cabling installed by Clark is visible, though the end of it runs out of the shop about twenty-five feet. The longest cabling is for external effects.]()

Here, extra cabling installed by Clark is visible, though the end of it runs out of the shop about twenty-five feet. The longest cabling is for external effects.

View fullsize

![The rest of the framework has been treated with compressed air, and moved into the shop for cabling run-through, and attaching to the rest.]()

The rest of the framework has been treated with compressed air, and moved into the shop for cabling run-through, and attaching to the rest.

View fullsize

![Every loom must go through in specific channels, to allow for module insertion.]()

Every loom must go through in specific channels, to allow for module insertion.

View fullsize

![Some cabling needs to run out of the initial section, then back in, to give everything room. No room for error when assembling, or the process has to be restarted.]()

Some cabling needs to run out of the initial section, then back in, to give everything room. No room for error when assembling, or the process has to be restarted.

View fullsize

![Finally, all the looms have been laid out across the fourteen feet of frame systems.]()

Finally, all the looms have been laid out across the fourteen feet of frame systems.

View fullsize

![A better view of the frame as a whole, with all sections now fully assembled.]()

A better view of the frame as a whole, with all sections now fully assembled.

View fullsize

![Patchbay, monitor section, and returns are now placed and cleaned. No power has yet been applied.]()

Patchbay, monitor section, and returns are now placed and cleaned. No power has yet been applied.

View fullsize

![Some beauty shots of the monitor and control section.]()

Some beauty shots of the monitor and control section.

View fullsize

![Nothing is more satisfying than a forest of knobs!]()

Nothing is more satisfying than a forest of knobs!

View fullsize

![While these have been functionally cleaned, they have not been completely cleaned.]()

While these have been functionally cleaned, they have not been completely cleaned.

View fullsize

![Doing so could take weeks of work, just on knobs, so that will have to wait for the next installation of the console.]()

Doing so could take weeks of work, just on knobs, so that will have to wait for the next installation of the console.

View fullsize

![The purpose of this build is only to sample the behavior of the console, and time is a factor.]()

The purpose of this build is only to sample the behavior of the console, and time is a factor.

View fullsize

![Knobs knobs knobs]()

Knobs knobs knobs

View fullsize

![Although there are a few missing button tops and fader caps, the vast majority are still here.]()

Although there are a few missing button tops and fader caps, the vast majority are still here.